LOADING

Welcome To :-----

Best Carbide Toolings

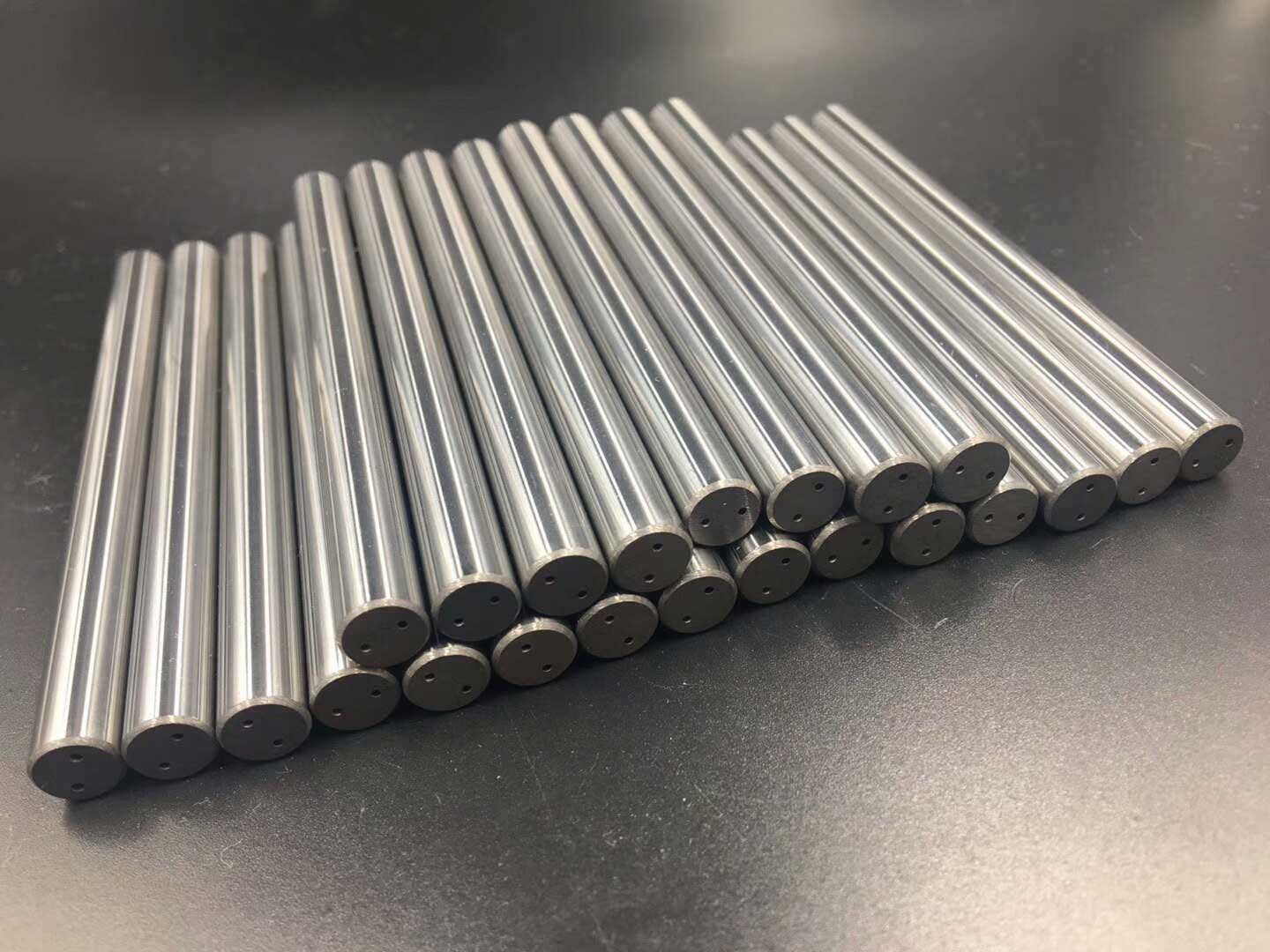

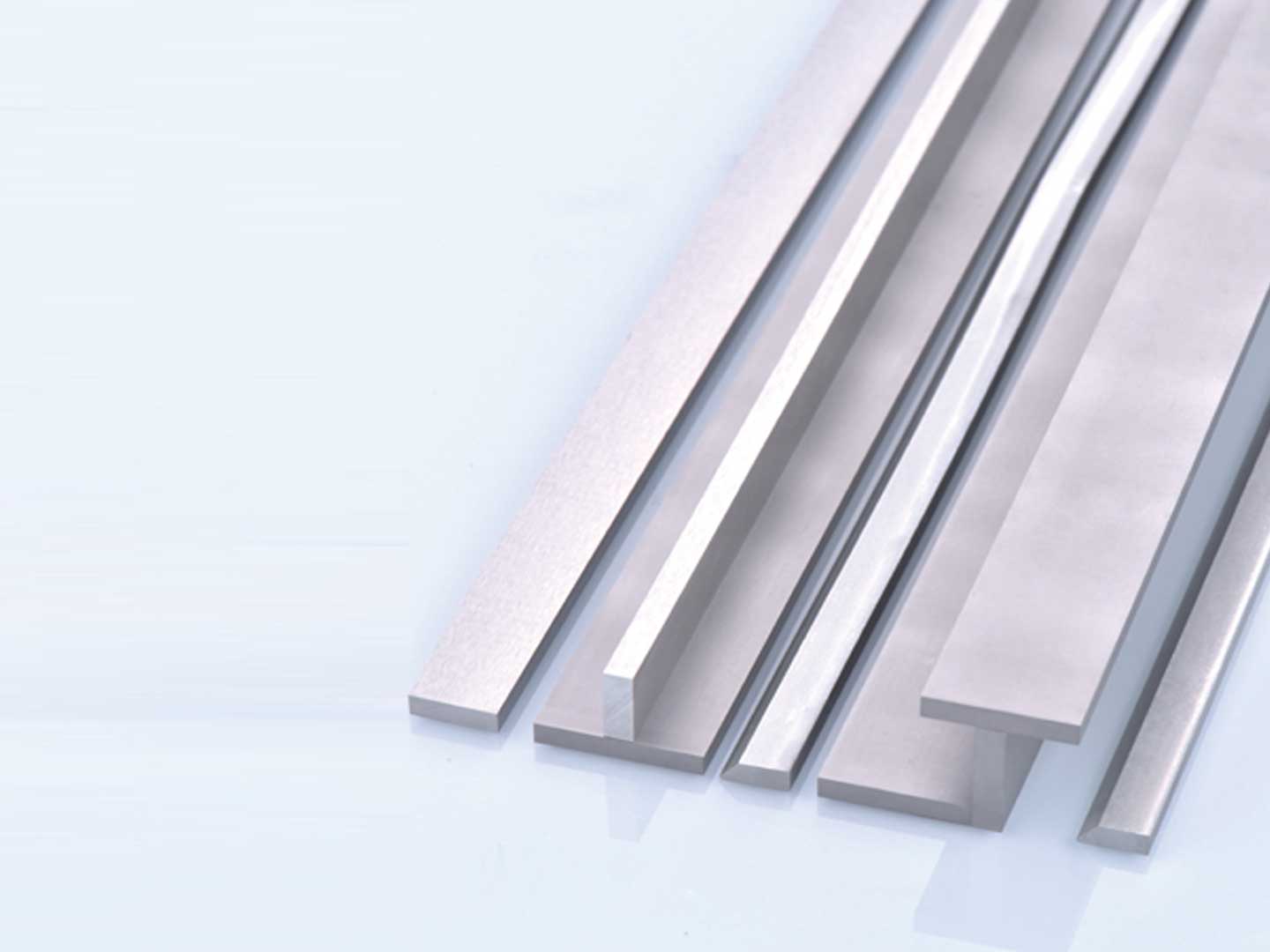

We are Importer, Supplier, Trader, Exporter of high quality Industrial Carbide Cutting Tools, Carbide Tools Raw Materials, Carbide Toolings, Cemented Carbide Rods, Solid Carbide Rods (SC Rods), Coolant Rods (Coolant Hole Rods / Coolant Cutting Rods / Coolant Carbide Rods), SC (Solid Carbide) Square / Rectangular Flats / Strips / Patti, Grades, Punches, End Mills, Carbide Tipped Tools, Ball Nose Cutters, Industrial Drills, Reamers, Milling Cutters from Pune, Maharashtra, India.

- Extensive Range of High-Quality Carbide Products

- Nationwide Supply Network with Strategic Location

- Association with Reputed Global Brands

- Industry Expertise and Customer-Centric Approach

More About Us

Call Us Now

+91 9326560006

-----: What We Offer :-----

Our Products

Company Facts

+

Satisfied Clients

+

Active Project

+

Winning Awards

+

Expert Teams

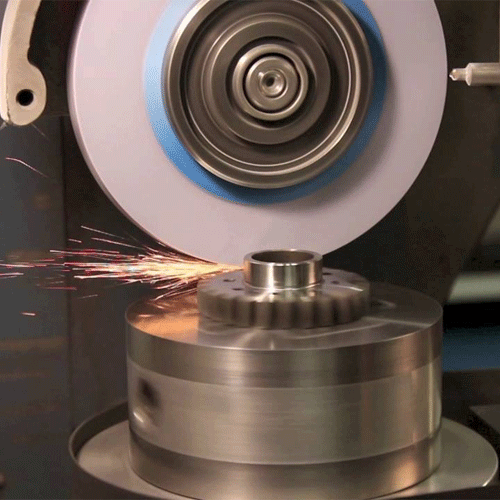

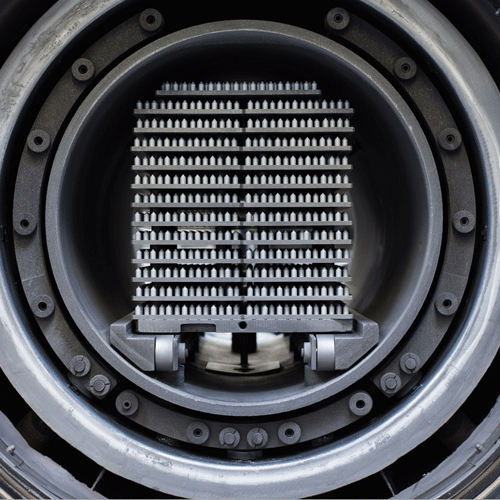

-----: Production Process :-----

Cemented Carbide Production Process

Client's Testimonials :------

Providing the Best Services for Our Customers

+

Active Reviews